Bemberg™ x Payal Pratap collaboration with colourful prints at FDCI X Lakmé Fashion Week

Through the collaboration Payal Pratap and Bemberg™ by Asahi Kasei show a new way of making fashion, based on merging craft & tech, cutting-edge materials and deeply rooted optimism in troubled times.

With a strong focus on prints, the designer, Payal Pratap, has worked on hand-painted artworks which have then been digitized. The designs capture detailed elements and a three-dimensional depth and texture from the age-old crafts of Batik, plus powerful imagery and minute detailing from the ancient craft of Chintz printing. Batik was named after the Javanese words “Amba” which means to write and “Titik”, which translates to a dot or a point, while Chintz comes from the Hindi word “Cheent”, meaning spotted or speckled. Both these techniques and crafts have been used in a contemporary context while creating the art works.

The prints encompass flora and fauna, bringing nature from the outside to the inside through the use of extensive flower, leaf, tree, vine and bird motifs, as an ode to sustainability. Placement prints have been engineered to make tailored jackets and structured pieces. A timeless collection comprising experimental pieces that blend the far east with India. A collection signaling holiday with a burst of colour. Bemberg™ in various avatars ranging from satins, muslins, mulmul, and silk blends have been used to create a collection with fluid drapes as well as structure.

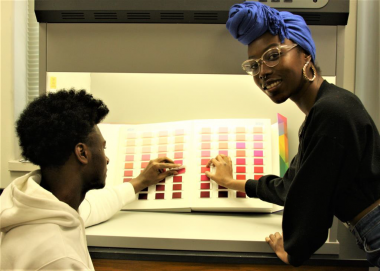

The fabric takes printing and colour beautifully and has a slight sheen and glazed feel which resonates with chintz. The colour palette ranges from indigos, browns, rust, to burgundy brick and gold. Furthermore, Bemberg™ is an inherently sustainable ingredient, since it is made with cotton linters, pre-consumer materials derived from the cotton oil industry, and converted through a traceable and transparent closed loop process. Coming from nature and going back towards nature, the Bemberg™ fiber is also biodegradable and compostable.

Asahi Kasei / C.L.A.S.S.