Entwicklung einer neuartigen Spinntechnologie zur Realisierung skalierbarer nano-, submikro- und mikrostrukturierter Faseroberflächen für technische und medizinische Anwendungen

Fibres Yarns Technical Textiles Medicine

Abstract

Das Hauptziel des IGF Projektes 21411 BR war die gezielte und reproduzierbare Oberflächenstrukturierung von Fasern während der Herstellung von Multifilamentgarnen. Dazu erfolgte die Entwicklung eines Verfahrens zur Herstellung von Bikomponentengarnen aus einem Grundpolymer und einer wasserlöslichen, strukturbildenden PVOH-Mantelkomponente. Durch das Herauslösen der Mantelkomponente in einem weiteren Prozessschritt werden dann nano-, submikro- und mikrostrukturierte Oberflächen erzeugt. Durch diese Verfahrensentwicklung sind nun erstmalig oberflächenstrukturierte Fasern herstellbar, die mit konventionellen Verfahren zur Oberflächenfunktionalisierung bisher nicht möglich waren. Der dazu notwendige Spinnprozess inkl. grundlegende Prozessparameter wurden im Projekt im Technikumsmaßstab erarbeitet. Die Nutzbarkeit der Ergebnisse wurde durch die erfolgreiche Erspinnung von Multifilamentgarnen mit strukturierten Faseroberflächen auf einer Pilot-Biko-Schmelzspinnanlage gezeigt. Die textiltechnische Verarbeitbarkeit der erzeugten Biko-Multifilamentgarnen erfolgte mit der erfolgreichen Umsetzung textiltechnischer Demonstratoren in Webversuchen.

Report

Einleitung, Problemstellung und Zielsetzung

Die kontinuierliche Entwicklung innovativer Technologien im Bereich der chemischen Faserproduktion ist entscheidend für die Fortentwicklung der gesamten Textilwirtschaft. Die gegenwärtige Fokussierung auf technische Textilien und medizintechnische Textilprodukte eröffnet vielversprechende Perspektiven für die deutsche Textil- und Faserindustrie. Diese aufstrebenden Märkte umfassen innovative Anwendungen, wie textiles Bauen, einschließlich komplex strukturierter architektonischer Membranen oder die Biomedizin mit Produkten, wie textile Implantate und Gewebsregenerationslösungen.

Ein neuartiger und vielversprechender Lösungsansatz ist die zielgerichtete Oberflächenstrukturierung der Fasern bereits während der Faserherstellung, um zum einen die Faseroberfläche zu erhöhen und zum anderen eine formschlüssige Anbindung der Matrix an die Faser zu erreichen. Diese Strukturierung auf der Einzelfilamentebene zeichnet sich durch regelmäßig oder stochastisch verteilte Nano- und Mikrostrukturen aus, darunter fibrillenartige Formationen. Dies führt zu einer definierten Oberflächenmorphologie und -topografie mit Kavitäten (Vertiefungen) und einer Oberflächenrauheit.

Für eine umfassende Nutzbarkeit dieser bisher unbekannten oberflächenstrukturierte Filamente, wurden im IGF Projektes 21411 BR „Nano, submikro- und mikrostrukturierte Fasern“ verschiedene Materialsysteme untersucht: das am Markt in großen Mengen verfügbare technische Polyester (PET - aromatischer Polyester), das im medizinischen Bereich häufig verwendete Polylactid Acid (PLA - aliphatischer Polyester) und ein High Density-Polyethylen (HDPE – Polyolefin). Basis für die Herstellung der strukturierten Fasern war eine Verfahrensentwicklung des Bikomponenten (Biko)-Schmelzspinnens. Kernpunkt dieser Entwicklung ist der temporäre Einsatz von wasserlöslichem Polyvinylalkohol (PVOH) als strukturformende Mantelkomponente im Fadenbildungsprozess. Eine anschließende Entfernung der strukturformenden Mantelkomponente entweder auf Garnebene oder auf Textilebene erzeugt dann die strukturierten Faseroberflächen im nano- (bis 0,1 μm), submikro- (0,1 ̶ 1 μm) und mikroskaligen (1 ̶ 2 μm) Bereich. Jeder dazu notwendige Entwicklungsschritt wurde von methodischen Material- und Prozesscharakterisierungen sowie gängigen physikalischen und chemischen Analysen begleitet, z.B. Untersuchungen der thermischen Eigenschaften des PVOH, der rheologischen Eigenschaften der Blend/PVOH-Mischungen sowie des Löslichkeitsverhaltens des PVOH aus dem Mantel der Biko-Fasern.

Erzielte Ergebnisse

Untersuchung der Schmelzspinnbarkeit von Polymer-PVOH-blends

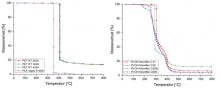

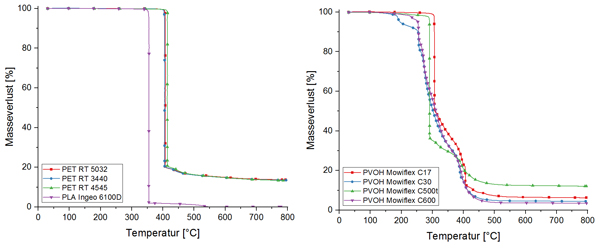

Besondere Kernaufgaben der gesamten Verfahrensentwicklung war die Identifizierung prozesstechnisch geeigneter Materialpaarungen zur Herstellung von Blend-Formulierungen für die Vorlage im Schmelzspinnprozess. Die Ableitung von Vorzugsformulierungen für das Schmelzspinnen erfolgte im Projekt anhand der physikalischen und rheologischen Eigenschaften der jeweiligen Polymer-PVOH-Blend-Formulierungen. Zur Darstellung der Schmelzspinnbarkeit wurden weiterhin die thermische Stabilität und das Degradationsverhalten verschiedener wasserlöslicher PVOH sowie der Compoundpolymere (PET, PLA bzw. PE) mittels thermogravimetrischer Analyse (TGA) bestimmt. Die ausgewählten Compoundpolymere zeigen eine Zersetzung unter Schutzgasatmosphäre erst bei Temperaturen von weit über 300 °C, wobei es eine zentrale Abbaustufe gibt (VGL: Abbildung 1, links). Die untersuchten PVOH-Typen weisen dagegen verschiedene Abbaustufen und Zersetzungsbereiche mit ersten auftretenden Abbaureaktionen ab 100 °C auf (vgl. Abbildung 1, links). Die Kristallisations- und Schmelztemperaturen sowie das Fenster der Verarbeitungstemperaturen wurden mittels dynamischer Differenzkalorimetrie (DSC) bestimmt. Besonderes Augenmerk bei der rheologischen Charakterisierung der PVOH-Materialien war die Identifikation zum jeweiligen Compoundpolymer sowie zu prozesstypischen Anforderungen (z.B. Extrusionsverhalten, Spinndüsendynamik) passender Viskositäten.

Abbildung 1: Ergebnisse der TGA Untersuchungen - Massenänderung in Abhängigkeit von Temperatur und Zeit unter Schutzgasatmosphäre (N2)

Erspinnung der nano-, submikro- und mikrostrukturierter Fasern

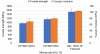

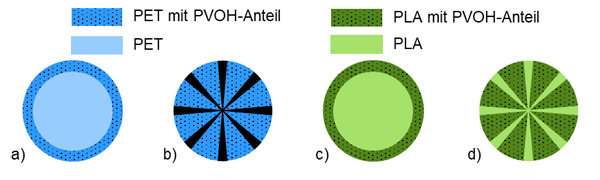

Die Erspinnung der grundlegend untersuchten Polymer (PET, PLA und PE-PVOH)-Blends zu Biko-Multifilamentgarnen erfolgte mittels der am ITM vorhandenen Biko-Schmelzspinnanlage. Die dafür notwendigen experimentellen Arbeiten zur Herstellung von Biko-Fasern durch Evaluierung verschiedener Spinnprozessparameter wurde systematisch umgesetzt, um ein tiefgründiges Verständnis für die Wechselwirkungen zwischen Garneigenschaften und Prozessparametern aufzubauen. Bei der Erspinnung wurden die Anordnungen Kern-Mantel- bzw. orange pie-Geometrie untersucht (Abbildung 2). Die prozessbegleitenden systematischen Untersuchungen umfassten die Charakterisierung der mechanischen und textil-physikalischen Eigenschaften. Aus den analytischen Untersuchungen und der Spinnprozessentwicklung wurde ein Spinnkonzept für die Erspinnung der Biko-Präkursorfasern für neuartige nano-, submikro- und mikroskalige strukturierte Fasermaterialien erstellt.

Abbildung 2: Ausgewählte Düsengeometrien a) core-shell aus PET und PET/PVOH, b) orange-pie aus PET und PET/PVOH, c) core-shell aus PLA und PLA/PVOH, b) orange-pie aus PLA und PLA/PVOH

Verfahrensentwicklung zum Herauslösen der strukturbildenden Stützkomponente (PVOH)

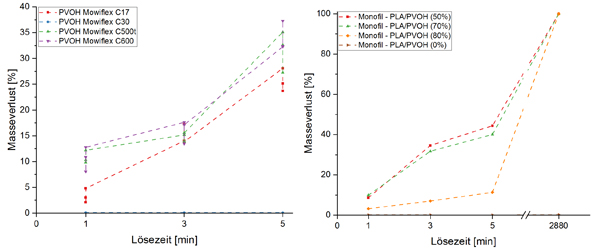

Zur Erzeugung der Oberflächenstrukturierung erfolgte die Entwicklung eines industrienahen Verfahrens zum Herauslösen der strukturbildenden Stützkomponente (PVOH) aus dem Fasermantel. Erforscht wurde das Herauslösen der Stützkomponenten aus den Biko-Fasern nach dem Verstrecken bzw. nach der textilen Flächenbildung. Ein kontinuierliches Lösen des PVOH im Spinnprozess war aufgrund des Unterschieds zwischen Fadenlaufgeschwindigkeit (≥ 100 m/min) notwendiger Lösezeit von PVOH (≥ 180 s, vgl. Abbildung 1) nicht umsetzbar.

Abbildung 3: Löseeigenschaften der PVOH-Typen in Wasser unter Raumtemperatur und leichter Strömung

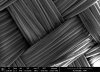

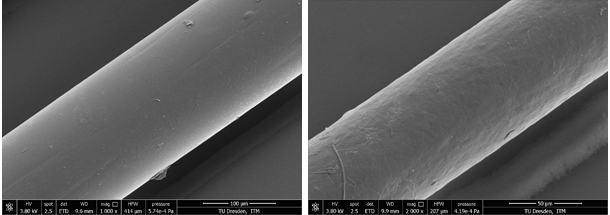

Besondere Aufmerksamkeit galt der Ermittlung relevanter Prozessparameter, wie Lösezeit und -temperatur, sowie der Auswahl des Lösungsmittels auf das Löseverhalten von PVOH, was in in zwei Entwicklungsstufen erfolgte: 1. Stufe - diskontinuierliches Herauslösen im Labormaßstab und 2. Stufe diskontinuierliche Löseversuche in einem Rolle-zu-Rolle-Prozess. Die Bewertung der Oberflächenstrukturierung erfolgte anhand von Lichtmikroskopie- und Rasterelektronenmikroskopie-(REM)Aufnahmen (Abbildung 4). Das entwickelte Verfahren zum gezielten Herauslösen von PVOH aus einem Multifilamentgarn ermöglichte die Erzeugung einer strukturierten Oberfläche. Die Optimierung der Prozessparameter sowie die praktische Umsetzbarkeit in einem kontinuierlichen Produktionsprozess sind die entscheidenden nächsten Schritte für die industrielle Anwendbarkeit dieser vielversprechenden Technologie.

Abbildung 4: REM-Aufnahmen Einzelfilamenten der Biko-Filamentgarne: (links) vor dem Herauslösen des PVOH aus der Mantelkomponente, (rechts) nach dem Herauslösen des PVOH aus der Mantelkomponente

Textiltechnische Verarbeitung der nano-, submikro- und mikrostrukturierten Fasern

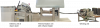

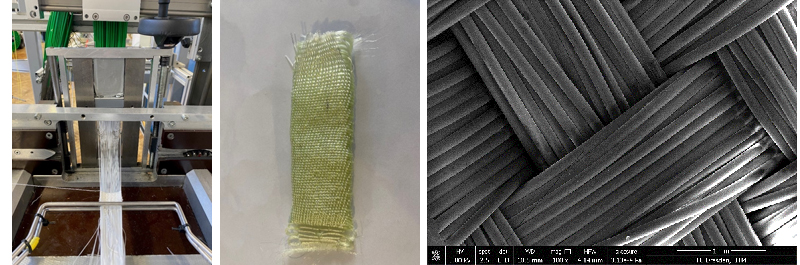

Die Beurteilung des Webverhaltens der ersponnenen Biko-Fasern erfolgte mittels Webversuchen auf einer Spulenschützen-Bandwebmaschine SL 150 (MAGEBA TEXTILMASCHINEN GMBH & CO. KG). Dabei wurde ein Standard-Polyestergarn als Kettfaden (16 Fäden/cm/Lage) eingesetzt. Das Biko-Garn wurde mittels eines Spulenschützen in Schussrichtung (7 Fäden/cm/Lage) eingebracht (vgl. Abbildung 5, links). Erfolgreich umgesetzt wurde in einem störungsfreien Webprozess ein zweilagiges, schlauchförmiges Gewebe mit Köperbindung in der oberen und Atlasbindung in der unteren Lage. Die Flächengebilde wurden mikroskopisch auf Filamentbrüche oder Fadenschädigung untersucht.

Abbildung 5: Textiltechnische Verarbeitung der Biko-Garne im Webprozess auf einer Spulenschützen-Bandwebmaschine (links); Zweilagiges, schlauchförmiges Gewebe aus Biko-Garn im Schussfaden und einem Polyestergarn in Kettfadenrichtung (rechts)

Zusammenfassung

Das Hauptziel des IGF Projektes 21411 BR war die gezielte und reproduzierbare Oberflächenstrukturierung von Fasern während der Herstellung von Multifilamentgarnen. Dazu erfolgte die Entwicklung eines Verfahrens zur Herstellung von Bikomponentengarnen aus einem Grundpolymer und einer wasserlöslichen, strukturbildenden PVOH-Mantelkomponente. Durch das Herauslösen der Mantelkomponente in einem weiteren Prozessschritt werden dann nano-, submikro- und mikrostrukturierte Oberflächen erzeugt. Durch diese Verfahrensentwicklung sind nun erstmalig oberflächenstrukturierte Fasern herstellbar, die mit konventionellen Verfahren zur Oberflächenfunktionalisierung bisher nicht möglich waren. Der dazu notwendige Spinnprozess inkl. grundlegende Prozessparameter wurden im Projekt im Technikumsmaßstab erarbeitet. Die Nutzbarkeit der Ergebnisse wurde durch die erfolgreiche Erspinnung von Multifilamentgarnen mit strukturierten Faseroberflächen auf einer Pilot-Biko-Schmelzspinnanlage gezeigt. Die textiltechnische Verarbeitbarkeit der erzeugten Biko-Multifilamentgarnen erfolgte mit der erfolgreichen Umsetzung textiltechnischer Demonstratoren in Webversuchen.

Danksagung

Das IGF-Vorhaben 21411 BR der Forschungsvereinigung Forschungskuratorium Textil e.V. wurde über die AiF im Rahmen des Programms zur Förderung der industriellen Gemeinschaftsforschung (IGF) vom Bundesministerium für Wirtschaft und Klimaschutz aufgrund eines Beschlusses des Deutschen Bundestages gefördert. Wir danken den genannten Institutionen für die Bereitstellung der finanziellen Mittel. Darüber hinaus möchten wir den Mitgliedern des Projektbegleitenden Ausschusses für ihre Unterstützung während der Projektbearbeitung danken.

Institut für Textilmaschinen und Textile Hochleistungswerkstofftechnik, TU Dresden